- 01Fill in

- 02Confirm

- 03Submit

The Possibilities Are Endless

The Possibilities Are Endless

"Carboflatex®" is our original heater material,

made by coating special polyester thread with conductive carbon paint and weaving it into a flat fabric.

It has excellent heat retention, safety, and stability,

and can be used for a wide range of purposes according to customer needs.

High Heat Retention

Carboflatex®uses carbon as the conductive thread material and emits far infrared rays. Also, the conductive threads are woven at very close intervals, so the entire fabric generates heat evenly.

It has a high heat retention effect, and the comfortable warmth unique to far infrared rays will penetrate into the body when it is used in a thermotherapy device.

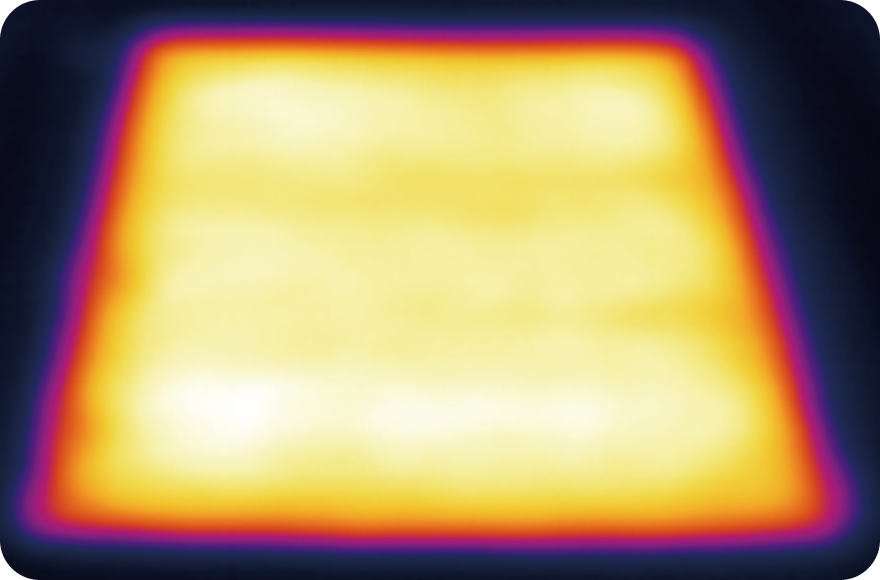

Thermographic image of Carboflatex® (Model: SM74). Heat is generated uniformly throughout the entire woven fabric.

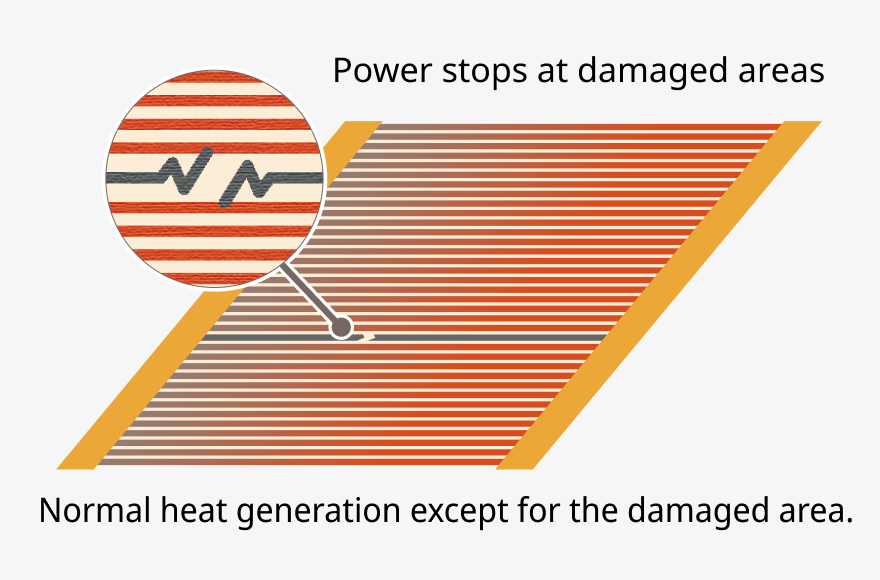

High Safety

Carboflatex®has a "self-fuse function" that automatically stops the electricity when the conductive thread melts at high temperatures. It prevents burn accidents caused by abnormal heat generation.

In addition, each conductive threads are seperated, so normal heat generation will be maintained except in the damaged areas.

Each conductive threads role as a fuse and the electricity stops when the conductive threads are dameged .

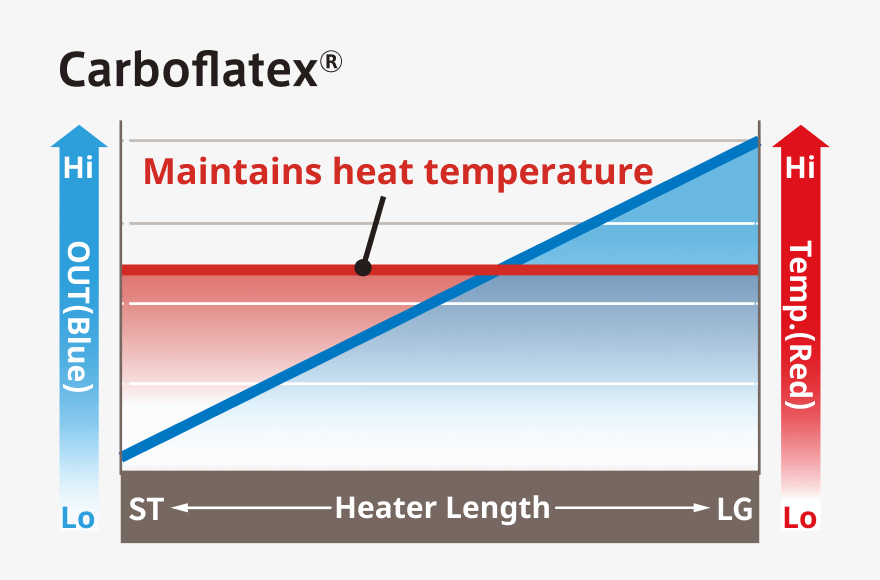

High Stability

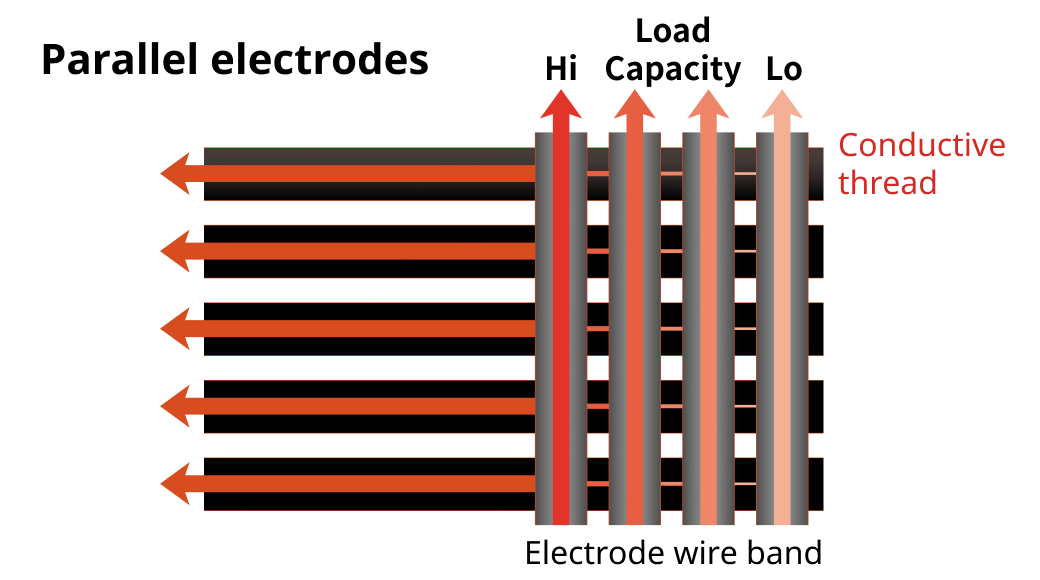

Carboflatex®uses parallel electrodes, so the heating temperature can be kept constant even if the product length or output (W) changes.

The heating temperature can be kept constant regardless of length, making it possible to offer a wide range of products.

Home electric potential and heat therapy devices, etc.

Concrete curing/Snow melting/Prevent freezing , etc.

Dome sauna etc.

Raising of seedlings.

Pig farming

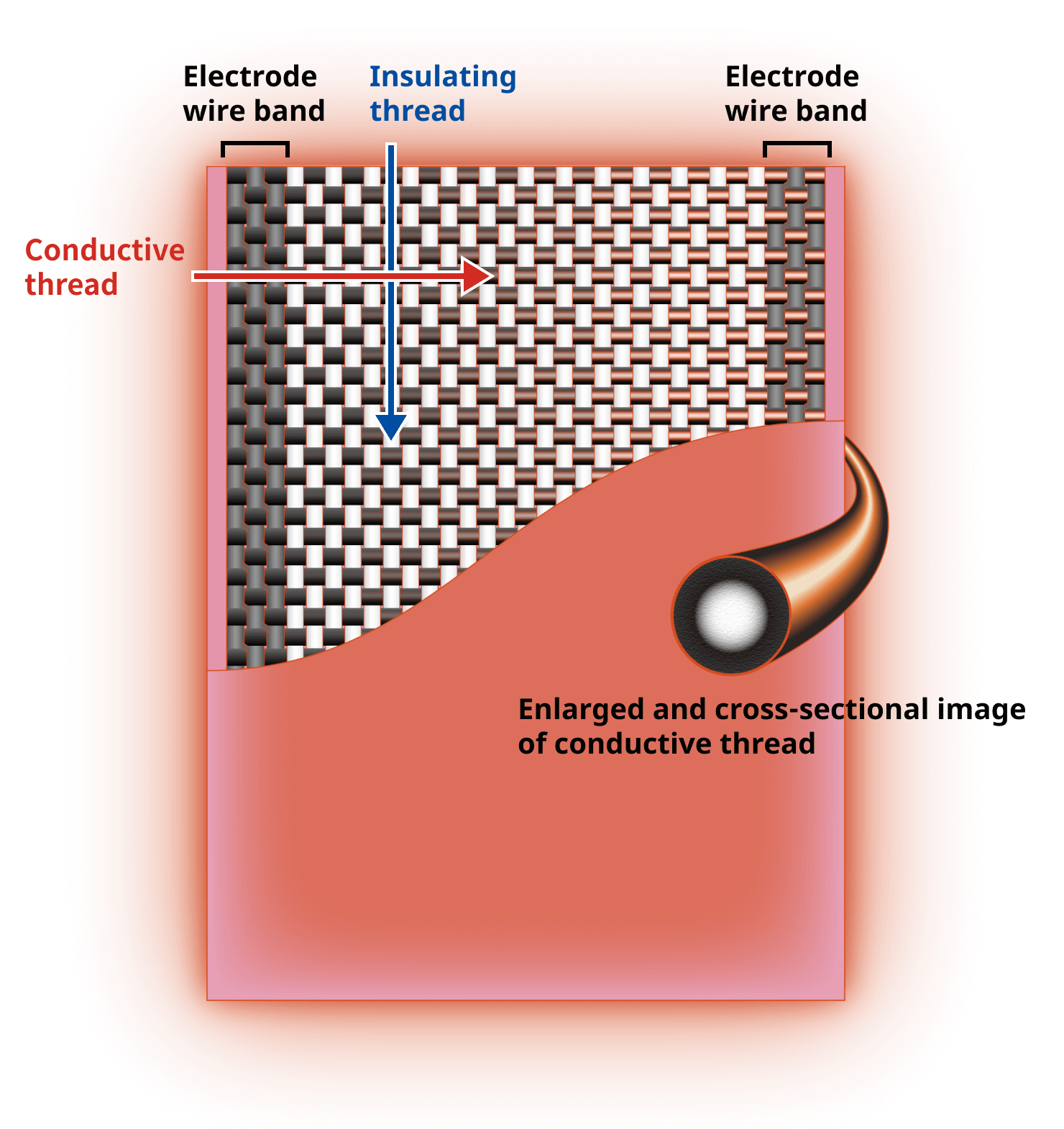

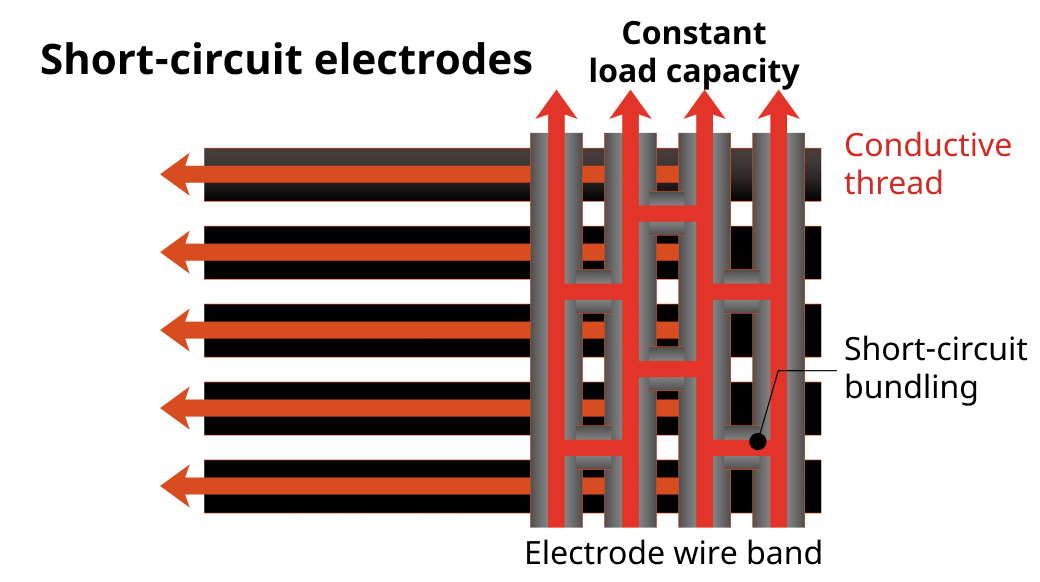

The electrode wire bands on the both edges of Carboflatex® are made up of multiple wires bundled together,

but each individual wire is tied together with a short-circuit wire.

This is our unique technology "short-circuit electrodes."

By using short-circuit electrodes, "The total capacity of each wire = The electrical capacity of the electrode wire band",

and making it possible to expand into long products that require large electrical capacity.

We can accommodate custom sizes to heat a wide area, such as melting snow or keeping livestock warm.

Conductive thread (weft, black) coated with carbon paint is woven together with insulating thread (warp, white) to create a woven fabric.

Heat is generated by passing electricity through the conductive thread between the electrode wire bands.

If there is no short-circuit bundling, a large load will be placed on the wires close to the heat generating part (inside),

but the capacitance load of all wires can be made constant by short-circuit bundling.

| Model | Heating width | Product width | Temperature | Voltage(AC) | Power(W/m) | Thickness | Weight (g/m) |

|---|---|---|---|---|---|---|---|

| SM75 | 750mm | 830mm | MAX 80℃ |

100V | 104W | 1.4mm | 1,208g |

| SM74 | 740mm | 800mm | 125W | 1,250g | |||

| SM54 | 540mm | 600mm | 74W | 1,000g | |||

| SM43 | 430mm | 500mm | 90W | 770g | |||

| SM32 | 320mm | 370mm | 138W | 600g | |||

| SM19 | 190mm | 260mm | 34W | 400g |

Is Made

Is MadeSTEP.1

Special polyester thread is coated with a specially formulated carbon paint to create conductive thread.

STEP.2

Conductive thread and polyester thread are woven together, then adhesive is coated to the fabric and dried.

STEP.3

Laminating the base fabric with polyvinyl chloride and provides sufficient insulation performance for indoor use.

First, conductive paint is coated to the polyester thread.

Next, a partner company weaves the conductive thread and warp thread into a fabric.

Then, adhere to the base fabric and dried, and finally the base fabric and insulating film are bonded together.

①Cutting ②Scribing ③Drilling holes in the electrode parts ④Resistance value inspection ⑤Insulation processing

⑥You can choose shipping forms from cut or rolled products.

(For cut products, we can handle steps ② to ⑤.)

*As of 2024

*As of 2024

※Image is for illustration purposes.

First of all, please contact us from the inquiry form on the site or telephone.

Click here for email inquiries

TEL.+81-978-64-1670

(Reception hours weekdays 8:30 to 17:30)

(Reception hours weekdays 8:30 to 17:30)

Based on the content of your inquiry, we will discuss your wishes, product image, order lot, etc. in detail as we proceed with the meeting.

We also provide advice on how to create products that meet your needs.

Based on the information we discuss, we will create a estimate.

After confirming the specifications, price, delivery date, transaction terms, etc., if you agree to the terms and conditions, we will officially sign a contract. Please note that the order will be officially accepted upon receipt of the purchase order.

Based on your request, we will create a heater that matches your image.

We manufacture our products with all our heart based on the technology we have cultivated over many years and thorough quality control, and conduct appropriate inspections before shipping.

New products can be delivered to customers in approximately 3 months.

We will carefully pack it and arrange for shipping and delivery.