Precision machining

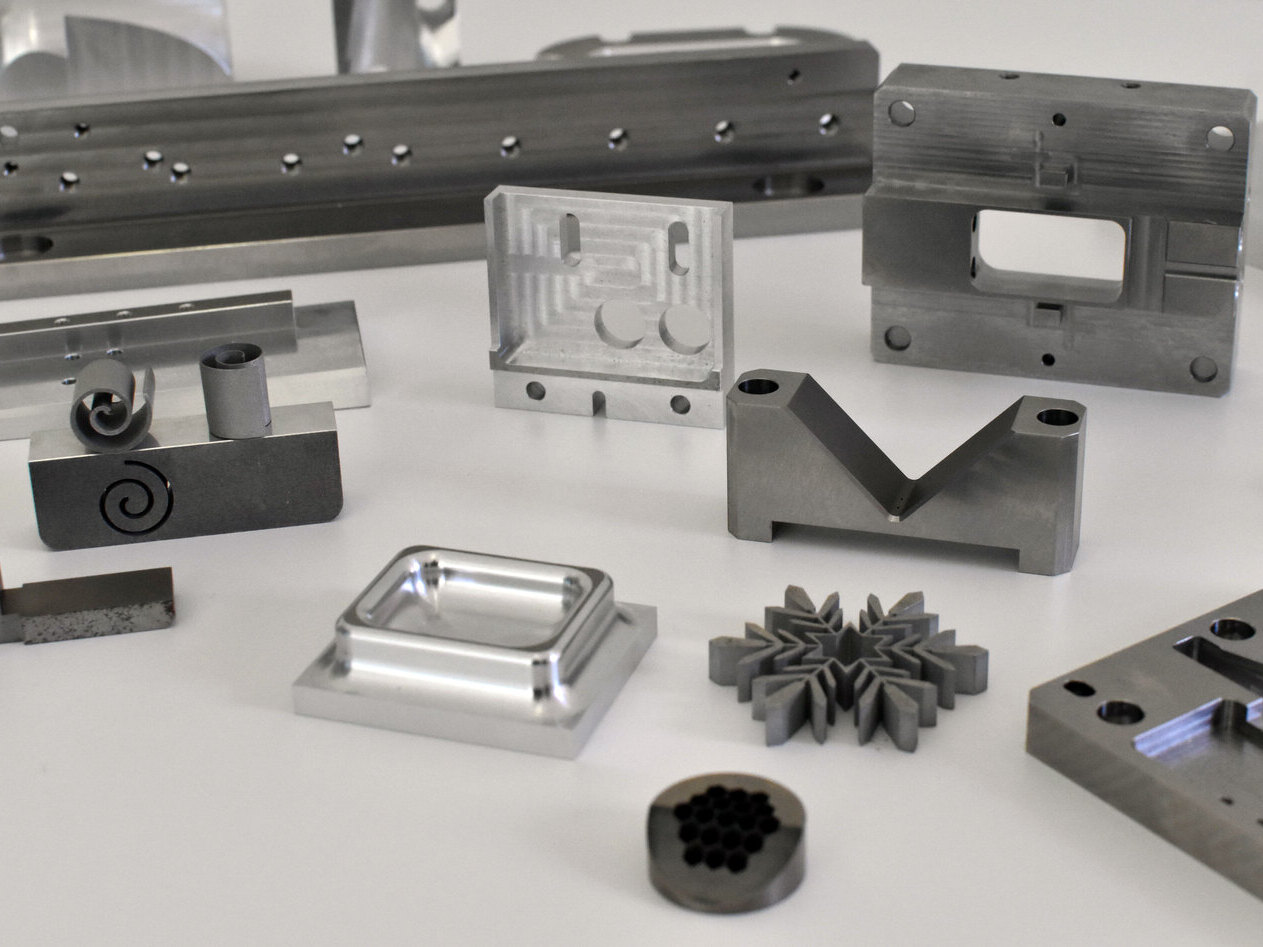

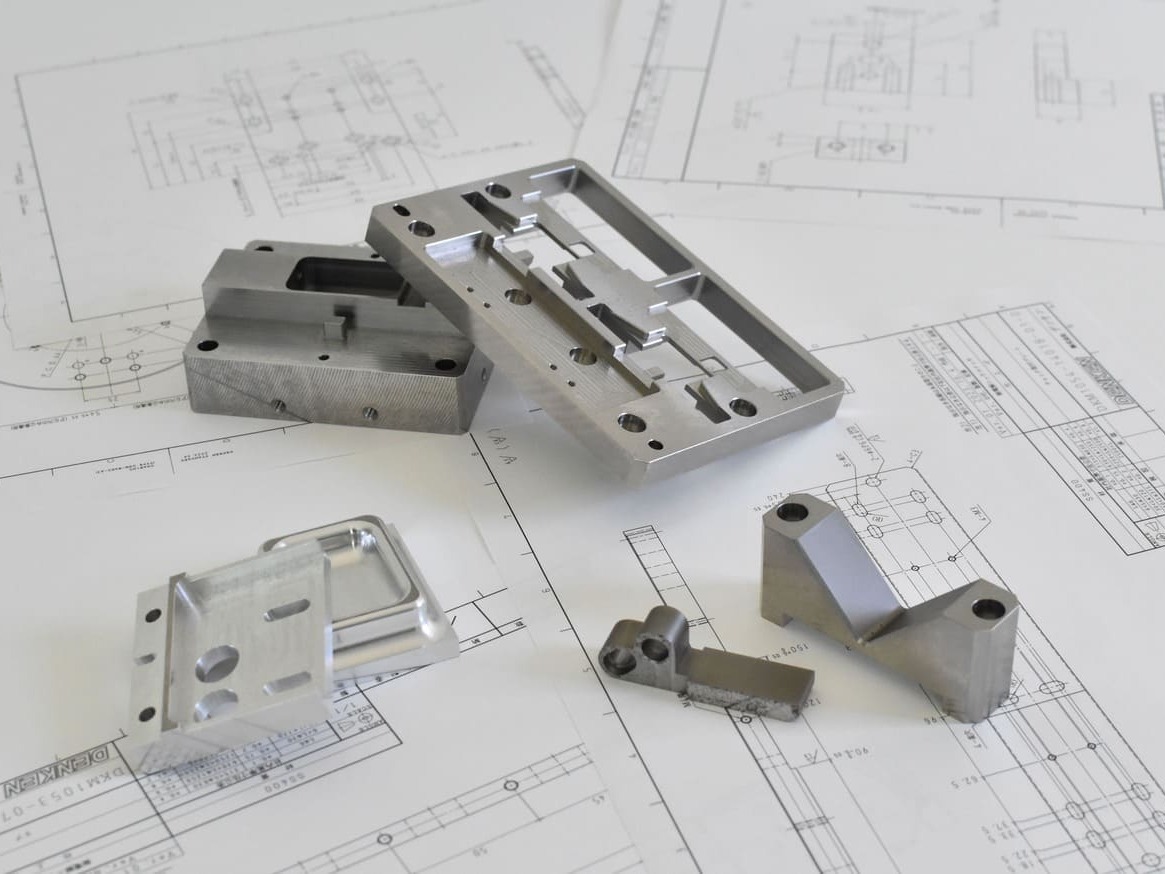

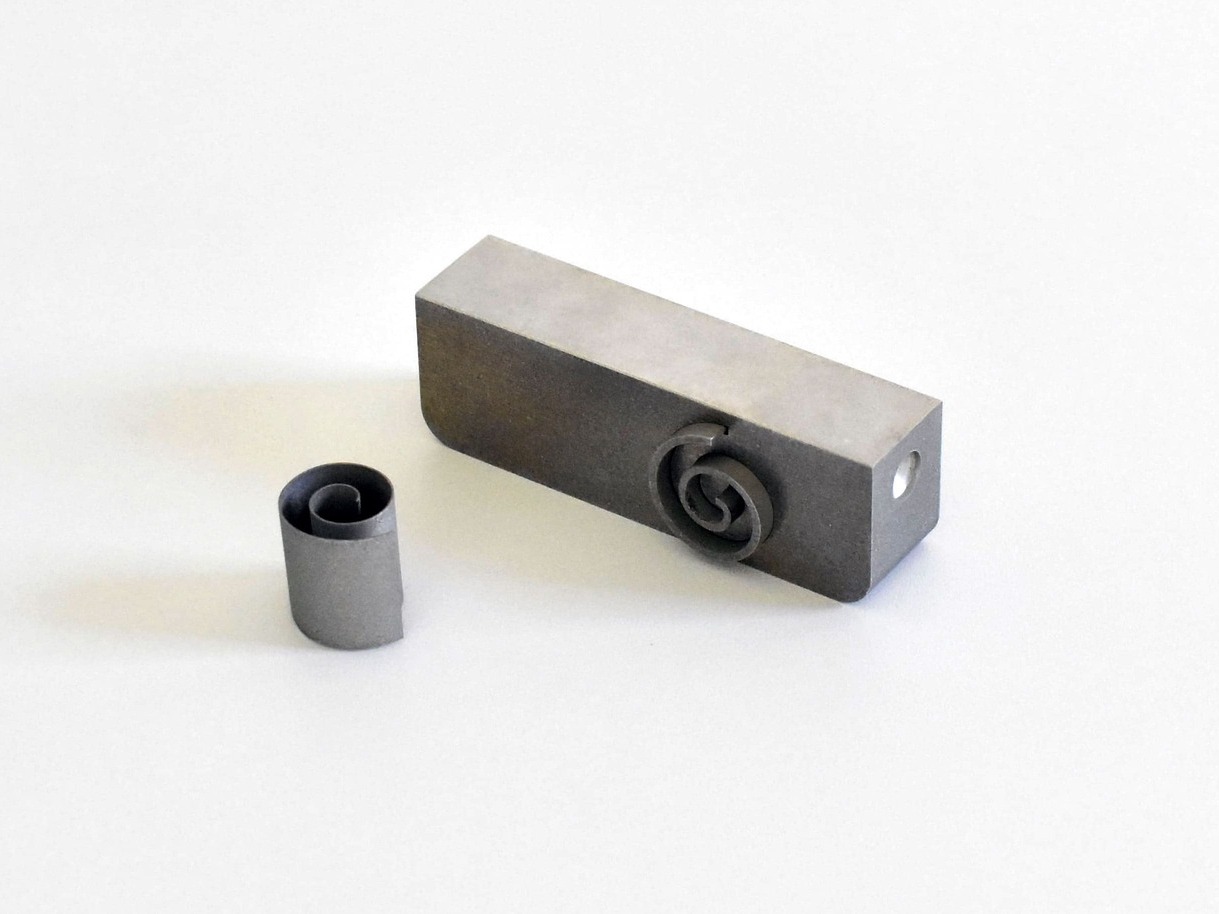

Process results

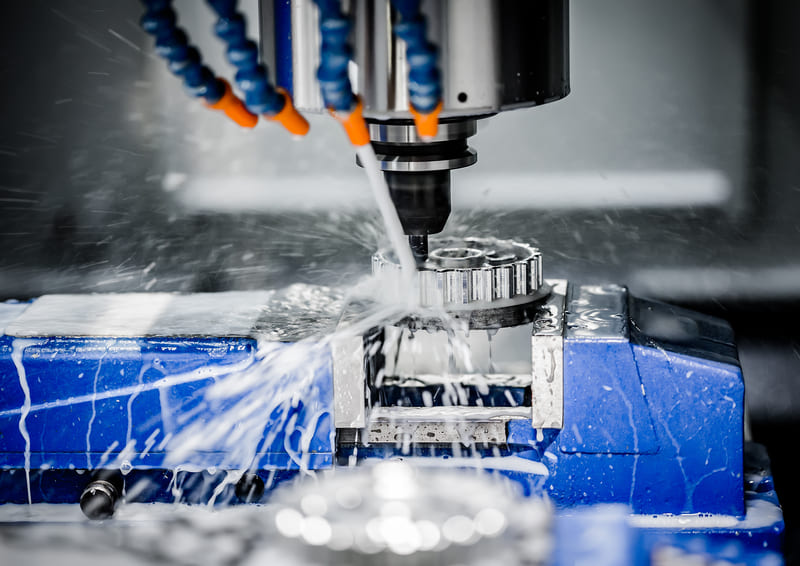

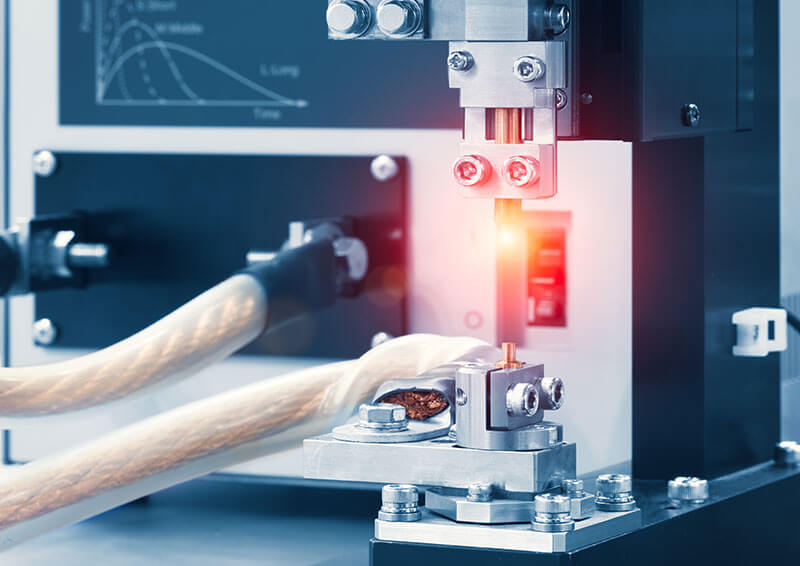

Machining

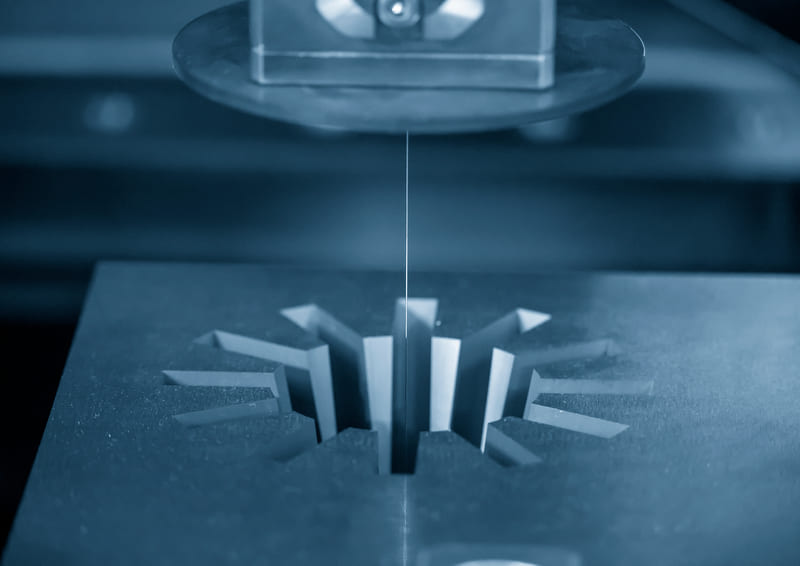

Wire discharge

Surface grinding

Inspection:CMM

Examples

Equipments

| CAD/CAM | Mastercam | 1 |

| Machining centres (vertical type No. 40) | DMGMORI NVX 5100 | 1 |

| DMGMORI CMX 600 V | 1 | |

| OKK VM53R | 1 | |

| MAZAK VCN-530C HS | 1 | |

| MAZAK VCN-510C | 1 | |

| MAZAK VCN-510C Ⅱ | 1 | |

| MAZAK VCS-430A LH | 1 | |

| Surface grinder | Okamoto PSG63DX | 1 |

| Wire-cut electrical discharge machine | Seibu M50A | 1 |

| CMM | Mitutoyo CRYSTA-Apex S7106 | 1 |

| Image dimension measuring machine | Keyence IM-8000 | 1 |

How to order

Contact

Please contact us if you have any concerns.Appointment

Based on the contents of the consultation, such as specifications, we will make proposals as many times as possible to ensure your satisfaction.Processing review/Process design

Machined and designed according to customer requirements.Prototype specifications determined

In the mass production of products, quality, function and design shape are repeatedly verified before moving to mass production.Prototype

Sample products are produced to ensure there are no problems before moving to mass production.Employment assessment

Performance assessment will help to identify design problems and areas for improvement.Mass production prototype and prcess

Before mass production, the product is manufactured and assembled in a form similar to the actual product to ensure that the function and design meet the design criteria and that mass production is feasible. Once mass production has been achieved, sales channels are secured, including component orders, product quantities and delivery dates.